Detailed Features:

1.Item Name: cast iron coulter for agricultural equipment

2.Material: High Chrome (ASTM A532, FBNi4Cr2BC, FBNi2hc,FBCr9Ni5, FBCr15MoNi,BS Grade 2A,2B, 2D, 2E, 3A, 3B, 3C, 3D, ASTM B Ni-Cr-LC, ASTM A Ni-Cr-HC, D Ni-HiCr)Ductile Iron,Carbon Steel,Alloy Steel

3.Surface treatment:spray-coating,painting,polishing,plating,passivation,etc

4.Application:agricultural tillage equipment

5.Place of Origin: Ningbo, China

6.Software for drawings: PDF, Auto CAD, Solidwork, JPG, ProE

7.Main production equipment: Wax injection,CNC-machine,Machine-center,Heat treatment Furnace, automated stamping production line

8.Main process: casting,heat treatment

Our advantages:

Introduction of Nord Machinery Co.,Ltd:

Nord Machinery Co.,Ltd is a leading foundry based in Ningbo,China. Equipped with first-class casting,heat treatment, blasting,surface treatment manufacturing,stamping facilities,we have been dedicated to lost wax casting(silica sol casting/stainless steel casting,water glass casting), lost foam casting,sand casting in cast steel&iron.We focus on customer's specific requirements.Apart from casting agricultural spare parts,we also cast any custom parts used in other industries,such as mining machinery,construction machinery,agricultural equipment,hydraulic&pneumatic equipment,energy power equipment,etc.

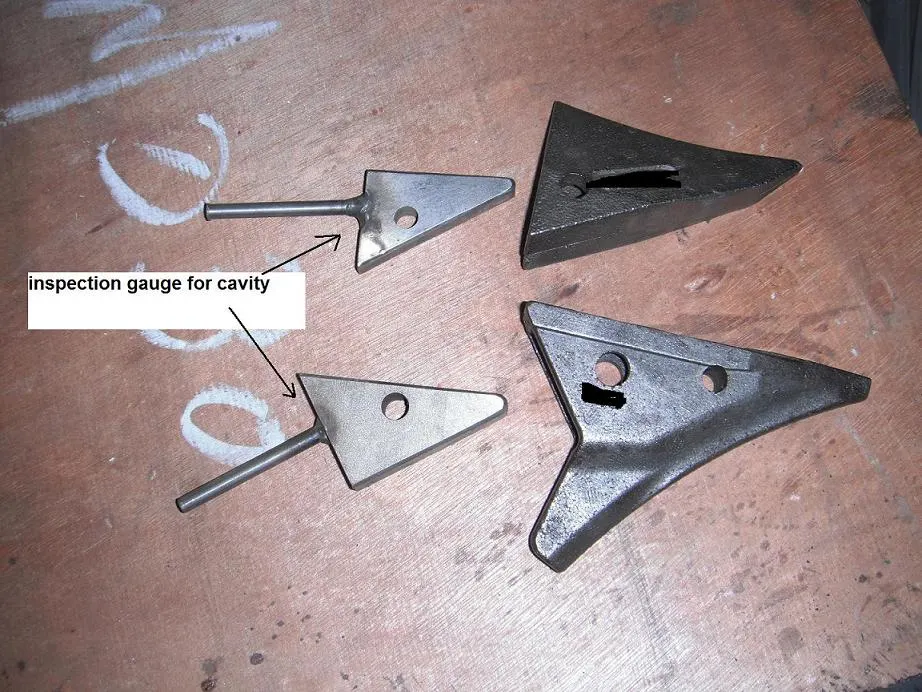

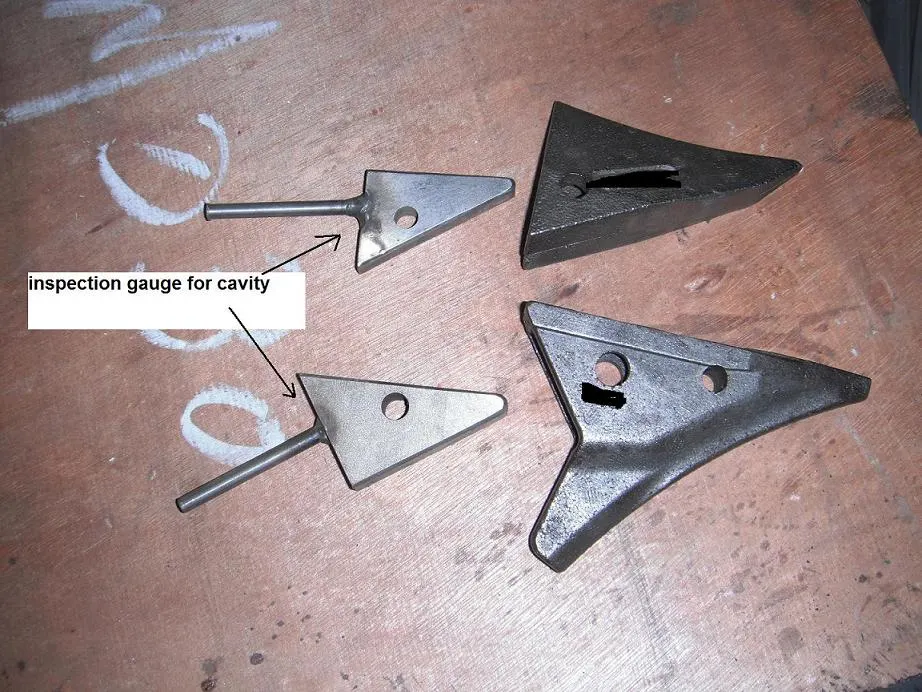

Inspection gauge:

1.Item Name: cast iron coulter for agricultural equipment

2.Material: High Chrome (ASTM A532, FBNi4Cr2BC, FBNi2hc,FBCr9Ni5, FBCr15MoNi,BS Grade 2A,2B, 2D, 2E, 3A, 3B, 3C, 3D, ASTM B Ni-Cr-LC, ASTM A Ni-Cr-HC, D Ni-HiCr)Ductile Iron,Carbon Steel,Alloy Steel

3.Surface treatment:spray-coating,painting,polishing,plating,passivation,etc

4.Application:agricultural tillage equipment

5.Place of Origin: Ningbo, China

6.Software for drawings: PDF, Auto CAD, Solidwork, JPG, ProE

7.Main production equipment: Wax injection,CNC-machine,Machine-center,Heat treatment Furnace, automated stamping production line

8.Main process: casting,heat treatment

Our advantages:

| 1 | 3D/2D Model drawing for exact dimension control |

| 2 | Prompt & Accurate quoation on requests |

| 3 | Production process tracking feedback in time |

| 4 | Secure & confidential contract |

| 5 | OEM service by custom-made |

| 6 | Absolute quality warranty |

Nord Machinery Co.,Ltd is a leading foundry based in Ningbo,China. Equipped with first-class casting,heat treatment, blasting,surface treatment manufacturing,stamping facilities,we have been dedicated to lost wax casting(silica sol casting/stainless steel casting,water glass casting), lost foam casting,sand casting in cast steel&iron.We focus on customer's specific requirements.Apart from casting agricultural spare parts,we also cast any custom parts used in other industries,such as mining machinery,construction machinery,agricultural equipment,hydraulic&pneumatic equipment,energy power equipment,etc.

Inspection gauge: